Hole punching and stamping

Punching is nothing more than cutting out a given material in order to obtain the desired shape. In itself, it is not a too complicated process, and the modern machines that are currently used for this make it possible to obtain virtually any imaginable shape. Stamping means a series of plastic working activities that shape various types of sheets.

Details

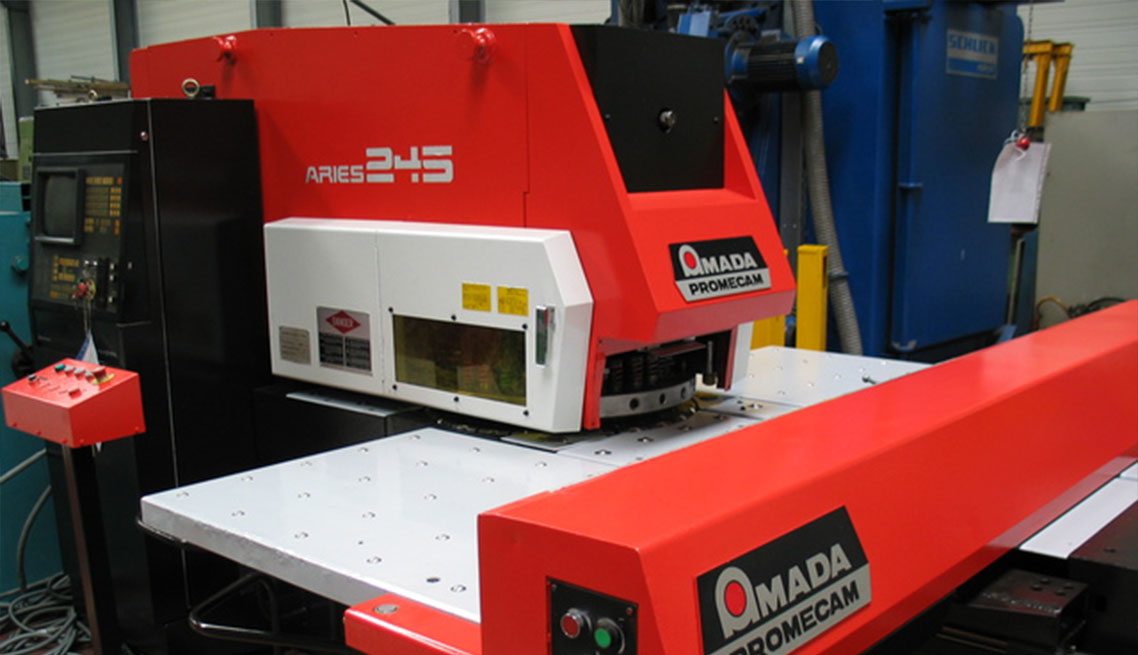

- Punching machine Amada Aries 245

- Black steel up to the thickness of 2mm

- Aluminum up to the thickness of 5mm

- Stainless steel up to the thickness of 1.5mm

- Working width 1000mm

- Geka 40 hole extruder

- Max. hole diameter Ø26

- Max. sheet thickness up to 13mm – black steel

Information

In our company, holes are made with an Amada Aries 245 turret punching machine. The work is performed by experienced employees who have completed many projects, including the most unusual ones, carried out in accordance with the customer’s instructions.

The punching machine can handle black steel up to a thickness of 2 mm, aluminum up to 5 mm and stainless steel up to a thickness of 1.5 mm. The working width is 1000 mm. We punch holes with the Geka 40 device. The maximum diameter of the extruded hole is Ø26, and the maximum thickness of the sheet in the case of black steel is up to 13 mm.